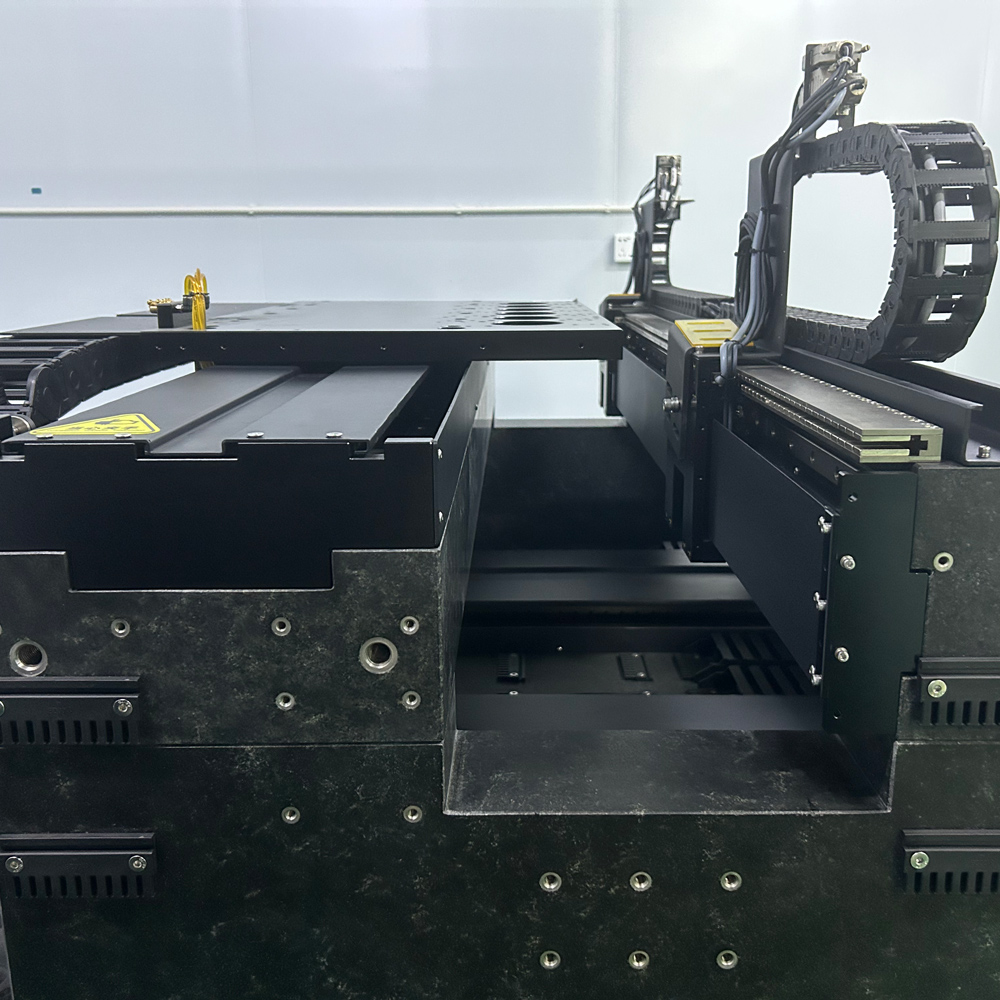

LDI exposure platform and its principle

(Laser Direct Imaging Exposure Machine) is equipment used in the manufacturing of printed circuit boards (PCBs). It utilizes laser beams to project circuit patterns onto photosensitive material, forming the desired circuit design. The LDI exposure machine is characterized by its high precision, speed, and efficiency, significantly improving the quality and productivity of PCB manufacturing. Additionally, it enables the production of multilayer circuit boards, catering to the needs of various customers.

Characteristics and Advantages of the LDI Exposure Machine:

1.High Precision: Advanced laser technology enables extremely high exposure accuracy and resolution, ensuring the precision and quality of PCBmanufacturing.

2.High Efficiency: The rapid exposure process enhances production efficiency in PCB manufacturing, reducing the overall production cycle.

3.Digitization: The digital exposure method allows for direct image generation from digital files, eliminating multiple intermediate steps in traditionalexposure processes and improving workflow efficiency.

4.Flexibility: It can be customized according to different PCB design requirements, making it suitable for various types of PCB manufacturing, offering highflexibility and adaptability.

Technical Parameters

| Technical Parameters | ||||

| Axial | X-axis | Y1/Y2-axis | Z1/Z2-axis | K-axis |

| Stroke | 900 mm | 1350 mm | 20 mm | 1195 mm |

| Load | 120 kg | ≥ 55KG+Z-axis’ weight | ≥ 55KG | 3(Side mounted) |

| Encoder resolution | 0.1 um | 0.1 um | 20 um | 0.1 um |

| Minimum step size | 0.5 um | 0.5 um | / | 0.5 um |

| Linear Positioning Accuracy | ±2.5 um | ±2.5 um | ±15 um | ±2.5 um |

| Bidirectional Repeatability | ±1.5 um | ±1.5 um | ±8 um | ±1.5 um |

| Horizontal Straightness | ±8 um | ±5 um | ±5 um | ±10 um |

| Vertical Straightness | ±12 um | ±12 um | ±5 um | ±10 um |

| yaw | 5 arc sec | 5 arc sec | 20 arc sec | ±15 um |

| pitch | 10 arc sec | 10 arc sec | For a point located 300mm from the center in the X and Y directions, during a 20mm movement along the Z-axis, the maximum error in the Z direction is ±30μm. | / |

| roll | 10 arc sec | / | / | ±10 um |

| yaw | ±2.5 arc sec/50mm | / | / | / |

| Pitch | ±5 arc sec/50mm | / | / | / |

Application Fields

The LDI exposure machine is a crucial technology in the PCB manufacturing industry and has broad application prospects. It is widely used in industrial projects that demand high precision and efficiency, such as : Laser manufacturing / Optical component manufacturing / Mechanical manufacturing /Photosensitive material manufacturing / PCB manufacturing / Electronics manufacturing / Communication equipment manufacturing

Product Features:

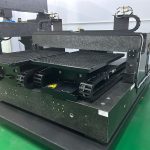

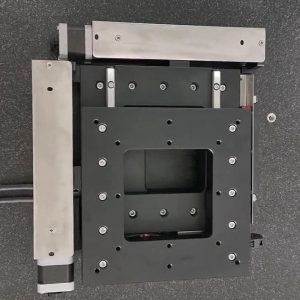

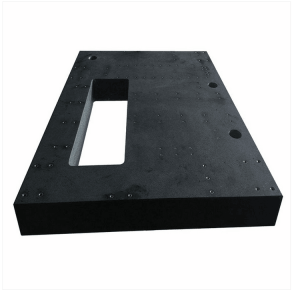

1.7-axis LDI exposure machine, fully equipped with coreless linear motors for direct drive control, eliminating cogging effect, allowing for smooth operation at lowspeeds (minimal speed fluctuation).

2.Utilizes high-precision linear guides.

3.Equipped with non-contact high-precision optical encoders, offering excellent dynamic performance, positioning accuracy, and repeatability.

4.Features high-precision optical grating position feedback.

5.Full-range repeatability is less than ±1.5μm.

6.Positioning accuracy is less than ±2.5μm.

7.Typically works in conjunction with a high-precision lifting axis (Z-axis).

8.Customizable according to customer requirements in terms of configuration, travel, load, and special structures.

Linear motor,Linear motors,linear electric motor,linear induction motor-bozhidacn.com

Linear motor,Linear motors,linear electric motor,linear induction motor-bozhidacn.com