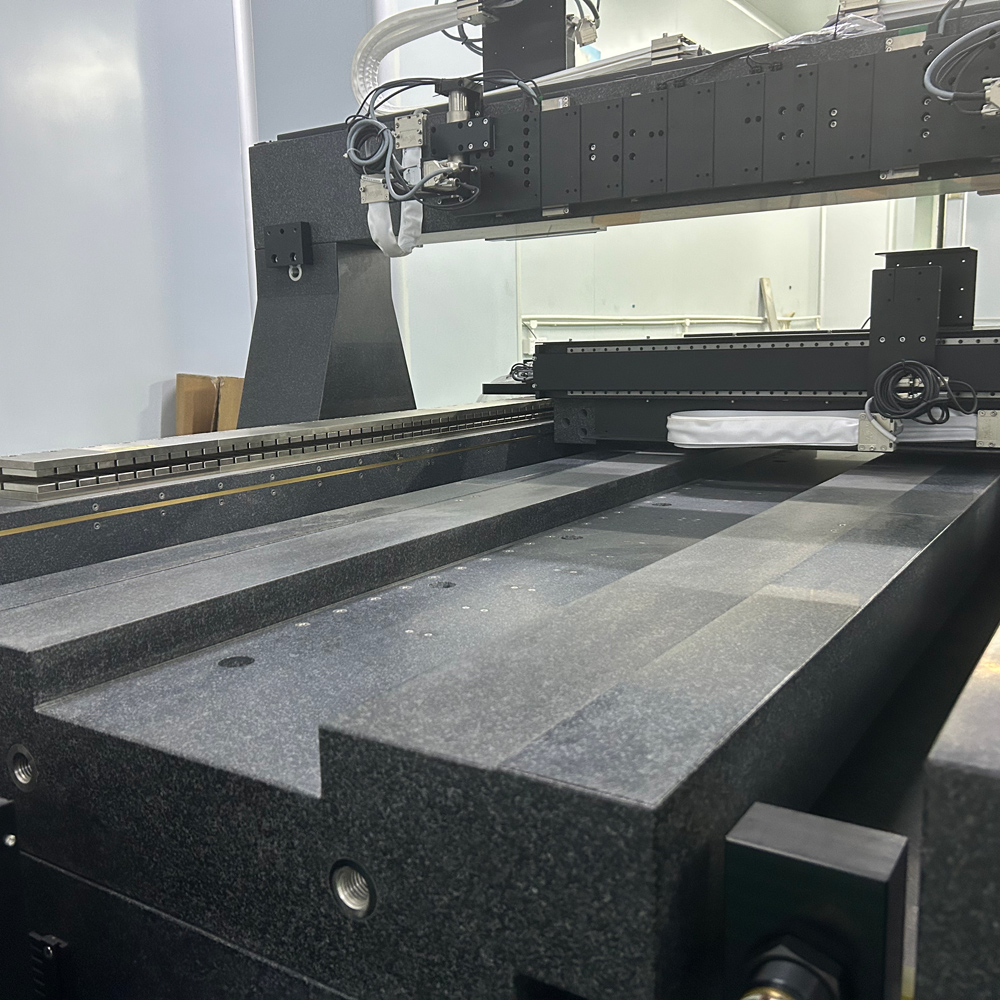

Air Bearing Platform and Its Principle

An air bearing platform is a suspension system that uses gas as the medium, employing the lift generated by gas flow to support and suspend objects, achieving a contactless suspension effect.

The principle involves injecting compressed air or nitrogen onto a planar interface. The flow of gas and the formation of bubbles generate lift that supports the suspended object, creating a layer of gas suspension. This enables high-precision processing, photolithography, and inspection, among other applications.

Characteristics and Advantages of the Air Bearing Platform

1.The air bearing platform offers extremely high precision and stability.

2.It has excellent load capacity and motion performance.

3.Maintenance costs are low due to its minimal friction coefficient, resulting in no wear or tear.

4.It ensures high linearity and flatness.

5.Due to its product characteristics, the air bearing platform has specific environmental requirements, necessitating use in a cleanroom.

6.It requires a clean, dry air source for operation.

Technical Parameters

| Technical Parameters | ||

| Axial | X-axis | Y-axis |

| Stroke | 900 mm | 1350 mm |

| XX straightness | 120 kg | ≥ 55KG+Z-axis weight |

| YY straightness | 0.1 um | 0.1 um |

| Positioning Accuracy | 5 arc sec | 5 arc sec |

| Repeat positioning accuracy | 10 arc sec | 10 arc sec |

| yaw | ±2.5 arc sec/50mm | / |

| pitch | ±5 arc sec/50mm | / |

Application Fields

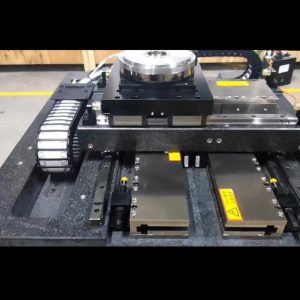

The dual-axis ultra-precision air bearing motion platform employs a structure optimized through finite element analysis and air bearing compensation design technology. This enhances precision while also providing the highest dynamic performance.

It is widely used in industries such as semiconductor processing and inspection, micro-nano fabrication, nano-level fly-cut polishing, and high-speed scanning.

Product Features:

1.Utilizes silicon carbide ceramic air bearing guides for ultra-high precision.

2.Speed of 1 m/s and acceleration of 4 g, ensuring quick settling time.

3.Dual-drive dual-gantry structure on the Y-axis, providing strong load capacity.

4.Optional grating or laser interferometer position feedback.

5.Customizable based on customer requirements, including configuration, travel, load, and special structures.

Linear motor,Linear motors,linear electric motor,linear induction motor-bozhidacn.com

Linear motor,Linear motors,linear electric motor,linear induction motor-bozhidacn.com