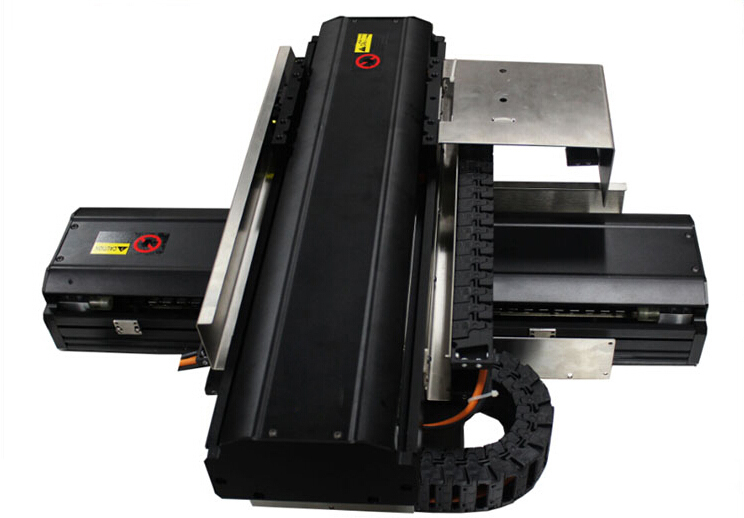

A Linear Motor Module is a component or subsystem that incorporates a linear motor into a modular unit for various applications requiring linear motion. It typically consists of a linear motor, which produces linear motion, along with additional components such as a slider, bearings, guideways, encoders, and control electronics.

The Linear Motor Module is designed to provide precise and efficient linear motion in applications such as CNC machining, semiconductor manufacturing, pick-and-place automation, and high-speed transportation systems. By integrating the linear motor into a modular unit, it becomes easier to incorporate into existing machinery or systems, as well as to scale up or modify according to specific requirements.

In CNC machining, for example, a Linear Motor Module might be used to drive the motion of the cutting tool or workpiece along the X, Y, or Z axes with high precision and speed. Similarly, in semiconductor manufacturing, Linear Motor Modules could be used for wafer handling, inspection, or lithography processes.

Overall, the Linear Motor Module provides a versatile solution for achieving smooth, accurate, and dynamic linear motion in various industrial and automation applications.

(1) High Efficiency:

Linear motors, compared to traditional hydraulic or pneumatic drives, boast higher power density and efficiency. They operate smoothly without noise, ensuring high-precision motion control.

(2) High Speed and Acceleration:

Linear motors exhibit very fast response times, enabling instantaneous start and stop actions. Acceleration and velocity can be adjusted by controlling current and control methods, giving them significant advantages in applications requiring fast and precise motion.

(3) High Reliability Over Long Durations:

Linear motors operate based on electromagnetic principles, thus avoiding any frictional losses or wear and leakage issues common in hydraulic cylinder and other power systems. Compared to other transmission methods, linear motors have longer lifespans and lower maintenance costs, making them more suitable for long-term and cyclical operations.

(4) Strong Flexibility:

Compared to traditional pneumatic or hydraulic drives, linear motors offer more flexible motion control and precise position control. They can also perform bi-directional motion, rapid acceleration and deceleration, among other functions, making them suitable for a wide range of applications.

(5) Easy Integration:

The lightweight and integrated nature of linear motors makes them easier to install and integrate with existing equipment. This allows linear motors to be quickly and simply integrated into automation control systems.

To select the appropriate type based on customer requirements, customer should consider several factors:

- Application Requirements: Understand the specific requirements of your application such as speed, precision, load capacity, and environmental conditions.

- Performance Specifications: Evaluate the performance specifications provided by different linear motor options, including speed, acceleration, repeatability, and positioning accuracy.

- Power and Efficiency: Consider the power requirements and efficiency of the linear motor to ensure it meets the energy demands and operational efficiency of your application.

- Reliability and Durability: Assess the reliability and durability of the linear motor, including its lifespan, maintenance requirements, and ability to withstand harsh operating conditions.

- Cost: Compare the cost of different linear motor options, considering both initial investment and long-term operating costs, including maintenance and energy consumption.

- Integration and Compatibility: Ensure that the chosen linear motor is compatible with your existing equipment and automation control systems, and assess its ease of integration into your application.

- Supplier Reputation and Support: Evaluate the reputation and support services provided by the linear motor supplier, including technical assistance, warranty coverage, and availability of spare parts.

All of our fiber optic cable package are with export wooden drum. Indoor FTTH cable’s wooden dimension is 50x50x32cm, delivery length 3km/drum, Outdoor fiber optic cable’s wooden dimension is 110cm*110cm*70cm, 0.85CBM, can be load about 33 drums for a 20GP.Also accept custom cable drum from customers. welcome to contact us!

GYTS Direct Burial Single Armored Double Sheath Fiber Optic Cable

GYTS Fiber Optic Cable Picture

Linear motor,Linear motors,linear electric motor,linear induction motor-bozhidacn.com

Linear motor,Linear motors,linear electric motor,linear induction motor-bozhidacn.com