Bozhida High Precision Linear Motor Factory

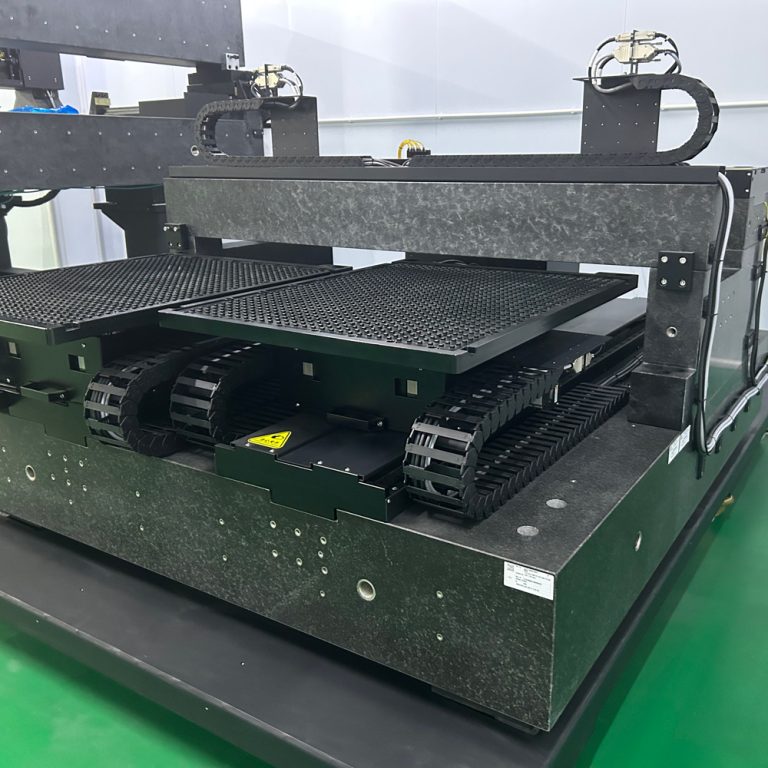

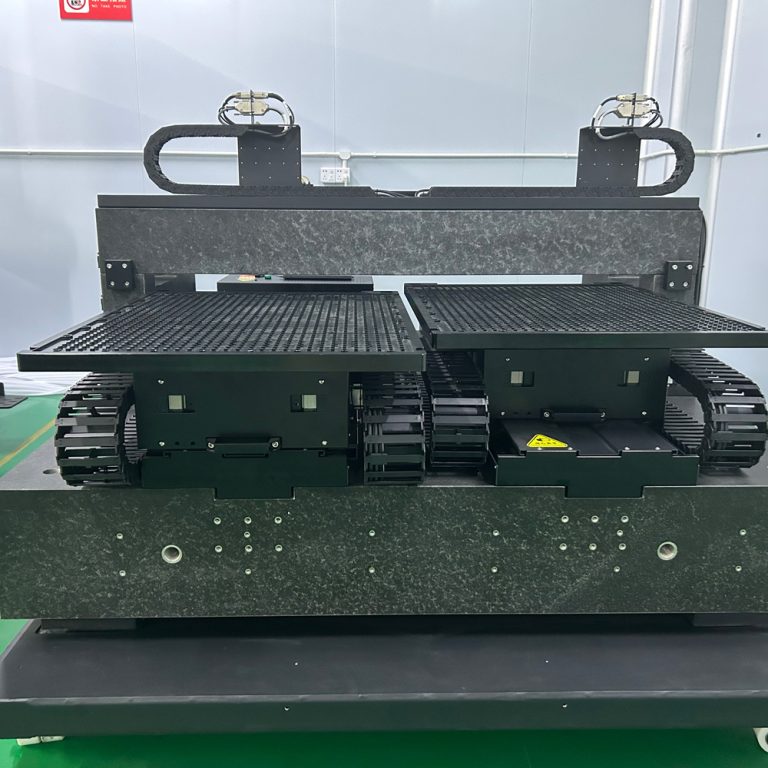

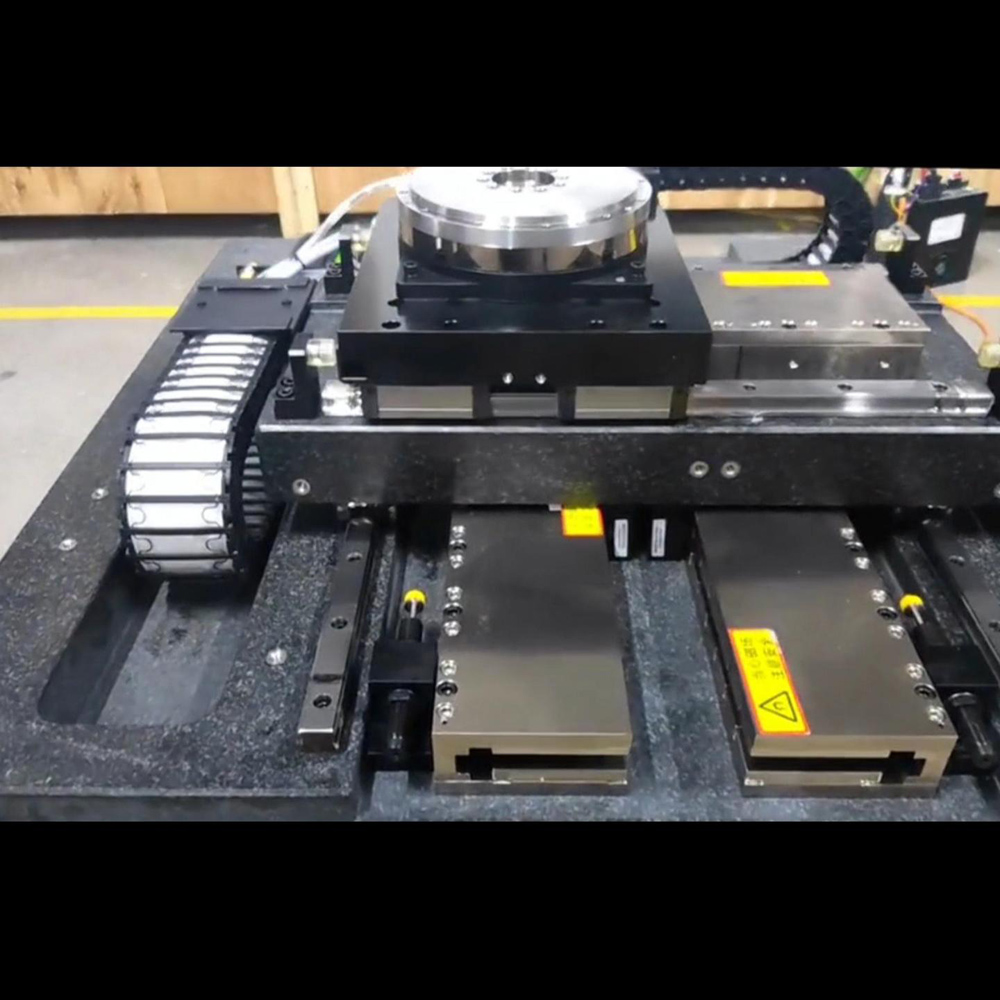

Product Features:

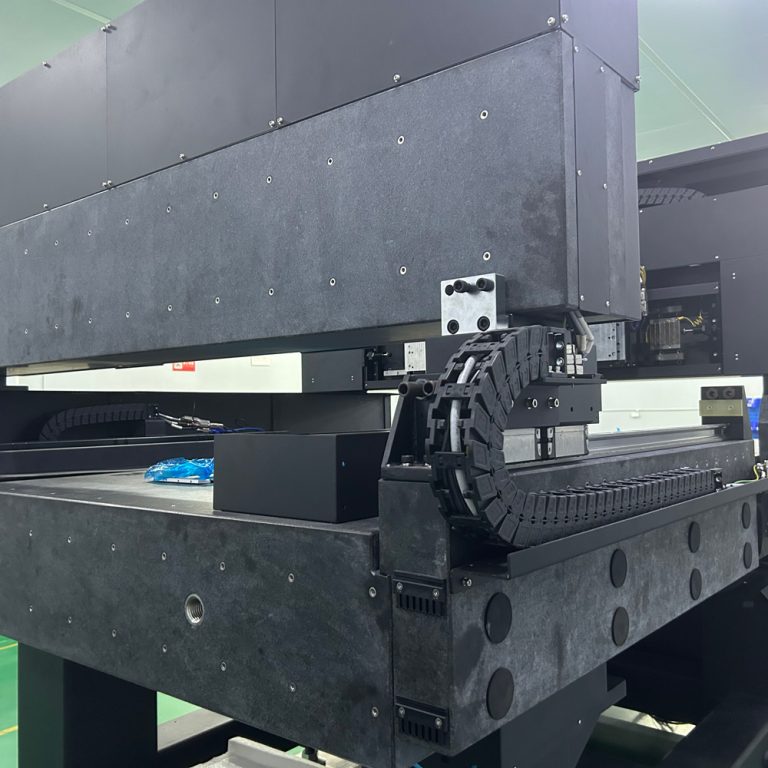

1.7-axis LDI exposure machine, fully equipped with coreless linear motors for direct drive control, eliminating cogging effect, allowing for smooth operation at low

speeds (minimal speed fluctuation).

2.Utilizes high-precision linear guides.

3.Equipped with non-contact high-precision optical encoders, offering excellent dynamic performance, positioning accuracy, and repeatability.

4.Features high-precision optical grating position feedback.

5.Full-range repeatability is less than ±1.5μm.

6.Positioning accuracy is less than ±2.5μm.

7.Typically works in conjunction with a high-precision lifting axis (Z-axis).

8.Customizable according to customer requirements in terms of configuration, travel, load, and special structures.

Product Features:

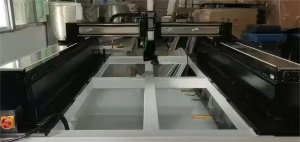

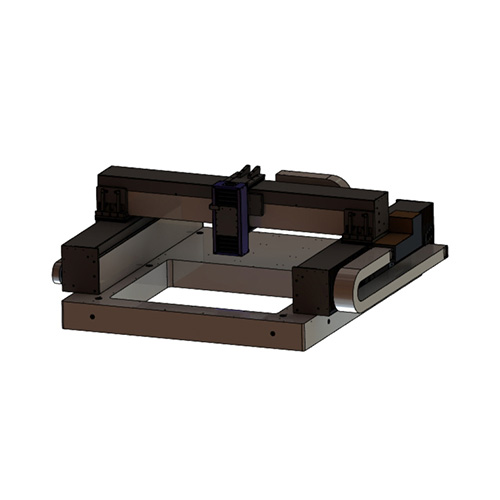

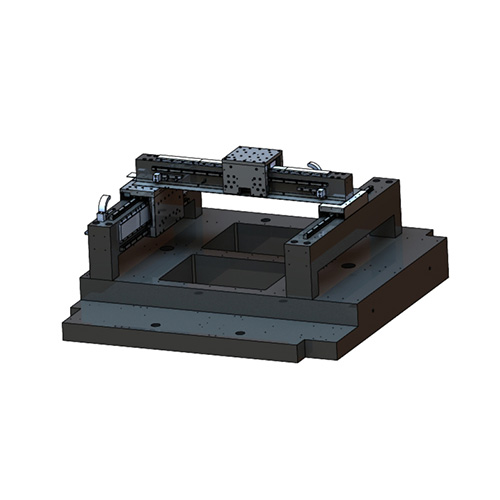

1.Gantry Structure: High stability.

2.Low Abbe Error: Ensures precision in measurements.

3.Compact Platform Structure: Offers strong driving capabilities.

4.Customizable: Can be tailored to customer requirements regarding configuration, travel range, load capacity, and special structures.

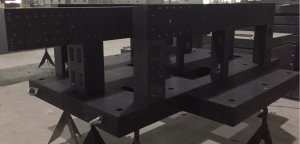

Application

This type of detection platform not only solves the inspection challenges in the panel industry but also extends its applications into the semiconductor industry through the display panel sector, offering vast potential in downstream markets. As display technology advances towards Micro LED technology, such high-precision detection platforms will become a crucial support for future display technologies.

It is particularly suitable for the inspection of LED chips in large panel manufacturing industries.

Stator & Linear motors

When a linear motor is in operation, the stationary part, which remains still, is called the stator. The primary function of the stator in a linear motor is to generate a magnetic field. It is composed of components such as the base, main magnetic pole, commutation pole, end cap, bearings, and brush device.

During the motion of a linear motor, it is necessary to collect the motor’s position information. The traditional method for position collection uses magnetic or optical gratings, but this approach is expensive and imposes strict requirements on the motor’s operating environment.

A linear motor is an electric motor that produces linear motion, as opposed to the rotary motion produced by conventional electric motors. Instead of a rotating shaft, a linear motor typically has a stationary component (often referred to as the stator) and a moving component (often referred to as the mover or slider). The mover is propelled along the length of the stator, generating linear motion.

Linear motors are often used in applications where precise and smooth linear movement is required, such as in industrial automation, semiconductor manufacturing, high-speed transportation systems (like maglev trains), and precision machining equipment. They offer advantages such as high speed, high acceleration, precise positioning, and the ability to eliminate mechanical transmission elements like belts or gears.

Bozhida provides timely after-sales service

Bozhida Robotics has a professional after-sales service team with over 50 production and research and development personnel. From conception to design, to dedicated tracking and team support services; It can meet the needs of a wide range of users 24/7. In order to better serve global customers.

We have established detailed customer profiles; We can provide professional services, including equipment installation, debugging, machine operator and administrator training, free technical support, etc.

Shenzhen BZD Robotics Co., Ltd. is a high-level provider of direct drive motion system solutions, with products sold in over 160 countries and regions worldwide. Bozhida provides customers with timely services and regular maintenance services. Xinfeng not only sells high-precision motion platforms to you, but also helps you complete continuous installation and operation steps. If you are interested in Bozhida’s automation equipment, please contact us.

Collaboration case

Products that you may be interested in

Application

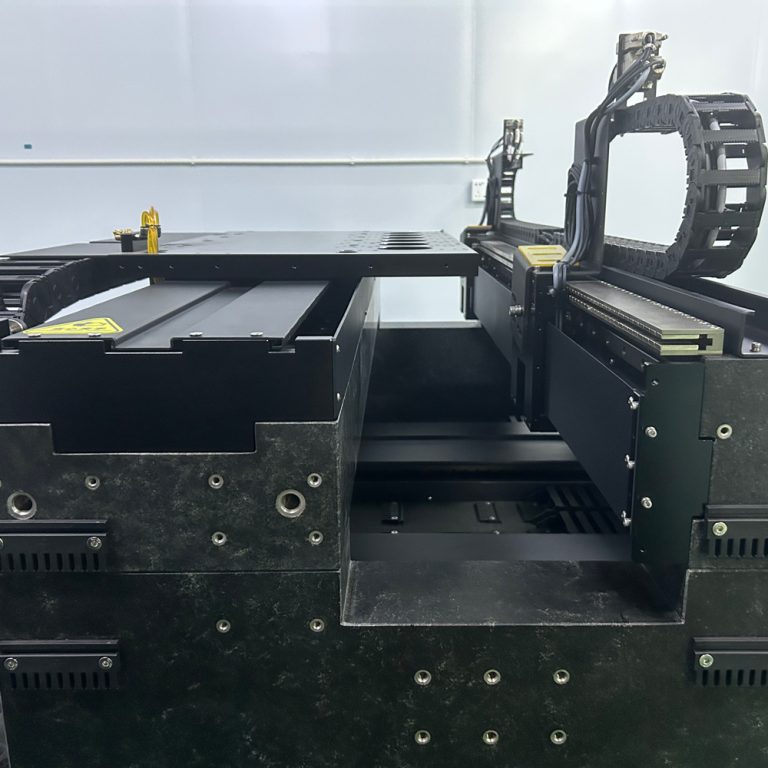

This platform is a precision motion table with a hollow structure, featuring large through holes and high dynamic performance. The alignment platform is widely used in fields such as optical measurement instruments, wafer alignment, LCD panel inspection, semiconductor processing, laser cutting and drilling, and composite machines.

Fixation-girder stage

The fixation-girder stage meets the modern precision manufacturing demands for high accuracy and efficiency. It is widely used in fields such as semiconductor manufacturing, precision mechanical processing, and optical instrument manufacturing.

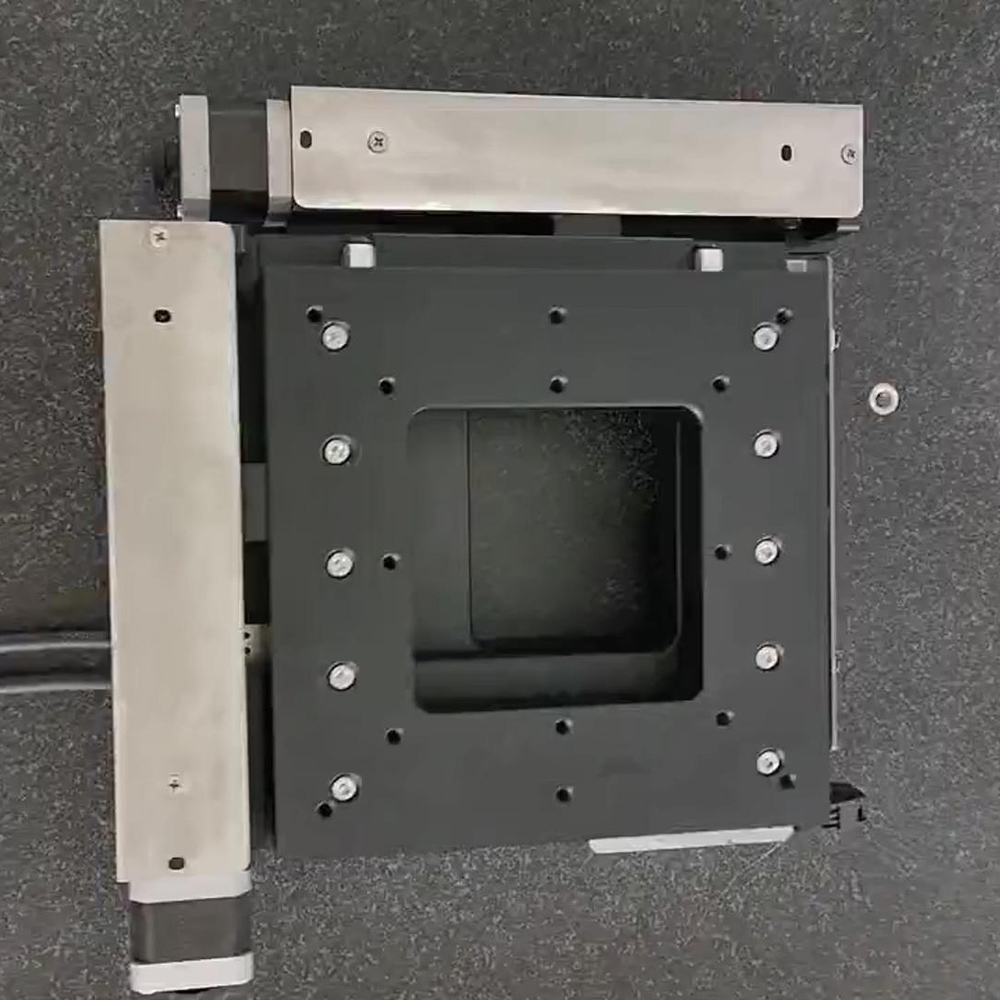

XYR AOI inspection stage

Used for measurement, counting, inspection, and intelligent judgment. Mainly applied in various fields, including automotive electronics, display inspection (such as digital tubes, LCD screens, and LED displays), pharmaceuticals, food, precision parts processing, dimension measurement, and product positioning

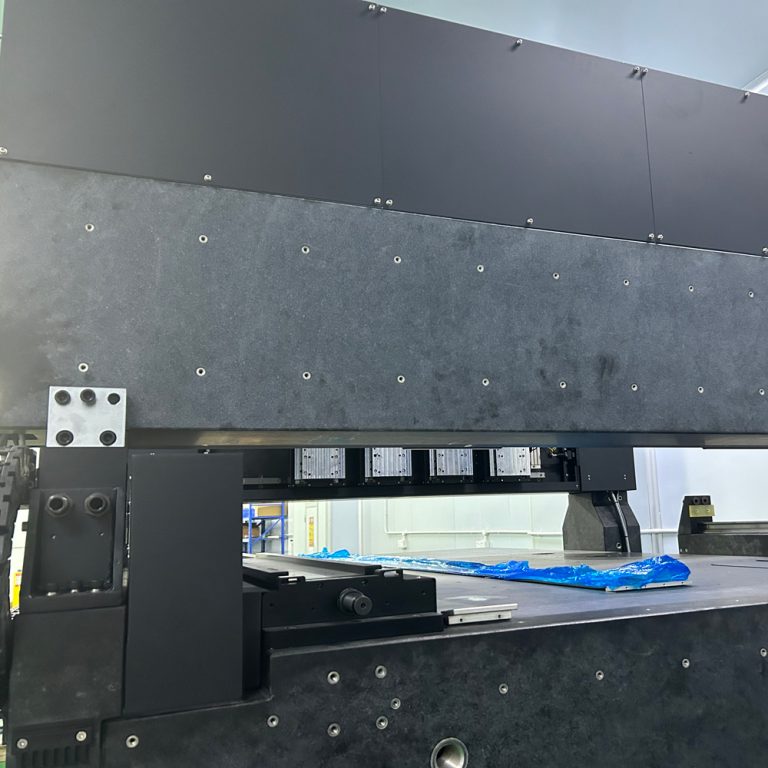

Dual-Drive Gantry

Product Features:

1.X, Y, Z worktables, with two axes arranged on a granite platform beam.

2.Gantry structure, the beam can move along the Y-axis.

3.X-axis achieves micron-level repeat positioning accuracy.

4.Maximum speed of 1000mm/s, maximum acceleration of 1.0g.

Dual-Drive Gantry

Product Features:

1.X, Y, Z worktables, with two axes arranged on a granite platform beam.

2.Gantry structure, the beam can move along the Y-axis.

3.X-axis achieves micron-level repeat positioning accuracy.

4.Maximum speed of 1000mm/s, maximum acceleration of 1.0g.

Coreless BZDU-30A Series

1.Height: 65mm, Width: 38.1mm

2.Continuous thrust: 26N ~ 130N

3.Peak thrust: 144N ~ 720N

4.Temperature rise suppressed to 0.07°C/W 5.Thrust ripple less than 0.15%

Linear motor,Linear motors,linear electric motor,linear induction motor-bozhidacn.com

Linear motor,Linear motors,linear electric motor,linear induction motor-bozhidacn.com

WeChat

Scan the QR Code with WeChat